Press releases

Miele introduces green aluminium to production

-

Production of primary aluminium for ovens uses 100% green electricity

-

CO2 emissions reduced by 645 tonnes per year

-

Purchasing director Krug: 'Another contribution to a future-proof economy'

Aluminium is both strong and light-weight. These and other properties make aluminium an attractive proposition in a broad range of industrial applications. Alongside its use in the automotive sector, this metal also plays a key role in the production of domestic appliances. Aluminium, though, is energy-intensive in production. Hence the more energy is supplied by the sun, wind and water, the more the climate benefits. As part of a pilot project, Miele is now using primary aluminium in the manufacture of ovens produced exclusively using green electricity from hydropower. This way, Miele reduces its CO2 footprint by 645 tonnes a year and, in doing so, is making yet another contribution to greater sustainability in the supply chain.

The procurement of green aluminium is the logical product of previously agreed measures. Miele first introduced the use of low-CO2 steel to the production of ovens in 2021, with the internationally operating family-owned company taking the lead once again in matters relating to emissions reduction. 'We are the first in our branch of industry to prove that CO2-reduced aluminium can be successfully used in ovens and help reduce the CO2 footprint', says Hans Krug, Senior Vice President Procurement. 'The objective is to use climate-friendly aluminium on a broad front and thereby contribute towards a future-proof economy', maintains Krug, outlining the strategy.

Initial use in oven production in the Westphalian town of Oelde

In a first stage, Miele will this year order around 150 tonnes of CO2-reduced aluminium for the production of trim. This represents an integral part of the ovens manufactured by Miele in the Westphalian town of Oelde. The aluminium is converted into an alloy in the supplier's own foundry, further processed and then supplied to Miele in the form of finished components. The aluminium is poured on lines which use regenerative burners which utilise waste heat from the production process. Compared with conventionally produced primary aluminium, this saves Miele 645 tonnes of CO2 per annum. Rouven Vierfuß, Plant Manager at Miele Oelde, lists a further benefit: 'To improve our sustainability act even further, having a circular economy plays a central role. The aluminium used in our ovens is 100% recyclable'.

About aluminium

Aluminium is a light alloy which on account of its material properties – for example, high electrical and thermal conductivity, a low density and being impervious to environmental influences – is used in Germany in particular in the automotive and aviation industries (48%), the construction industry (15%) and mechanical and electrical engineering (14%) (Source: GDA). With consumption currently standing at 2.1 tonnes, Germany follows China (33.3 m tonnes) and the USA (4.6 m tonnes) in third place as a user of primary aluminium on the world stage.

About Oelde

With approximately 670 employees, Oelde is the competence centre for the development and production of ovens, wall ovens, combination steam ovens, ovens with an integrated microwave and dialog ovens. Oelde belongs to the cooking technology division within the Miele Group and, as is the case with all other production plants for finished goods, is also characterised by a high degree of vertical integration and model diversity. Oelde joined Miele's portfolio of production sites in 1986.

Company profile: Miele is the world's leading manufacturer of premium domestic appliances including cooking, baking and steam-cooking appliances, refrigeration products, coffee makers, dishwashers and laundry and floor care products. Their product portfolio also includes dishwashers, washing machines and tumble dryers for commercial use as well as washer-disinfectors and sterilisers for use in medical and laboratory applications. Founded in 1899, the company has eight production plants in Germany, one each in Austria, the Czech Republic, China, Romania and Poland as well as two production plants belonging to its Italian medical technology subsidiary Steelco. Sales in the 2021 business year amounted to around € 4.84 bn. Miele is represented with its own sales subsidiaries and via importers in almost 100 countries/regions. Throughout the world, the family-run enterprise, now in its fourth generation, employs a workforce of around 22,300, of which approx. 11,200 employees work in Germany. The company has its headquarters in Gütersloh in Westphalia.

Dirk Haushalter

+49 5241 89-1027

dirk.haushalter@miele.com

Media information

| Description | Download |

|---|---|

Less CO2 in the supply chain: Miele’s Hans Krug, Senior Vice President Procurement (left), and Oelde plant manager Rouven Vierfuss show a profile strip made of aluminium. At the Oelde site in Germany, Miele installs the component in some of its ovens. The light metal was produced by the supplier using green electricity based on hydropower. (Photo: Miele) |

|

| High Resolution JPG | |

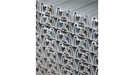

Less CO2 in the supply chain: In Oelde, Germany, Miele installs low-emission components such as these aluminum profile strips in some of its ovens. (Photo: Miele) |

|

| High Resolution JPG | |

Less CO2 in the supply chain: In Oelde, Germany, Miele installs low-emission components such as these aluminum profile strips in some of its ovens. (Photo: Miele) |

|

| High Resolution JPG |